3D-printed electric cars coming

Italy-based X Electrical Vehicle, or XEV, expects to launch its mass-producible 3D-printed LSEV electric cars in China from the second quarter of next year, a senior designer of the company said in Shanghai on Monday.

The startup electric vehicle company is exhibiting its first 3D-printed LSEV at Shanghai's China 3D-printing Cultural Museum, a month ahead of its show in Auto China 2018 in Beijing, according to Guo Xiaozheng, a senior designer from XEV.

"Before the mass production, XEV has received 7,000 orders, and many Chinese companies have shown interest toward our products," said Guo.

The vehicle is going to become available in the second quarter of 2019, and the XEV team will constantly improve the car model according to market feedback, including offering customers tailor-made features from time to time, added Guo.

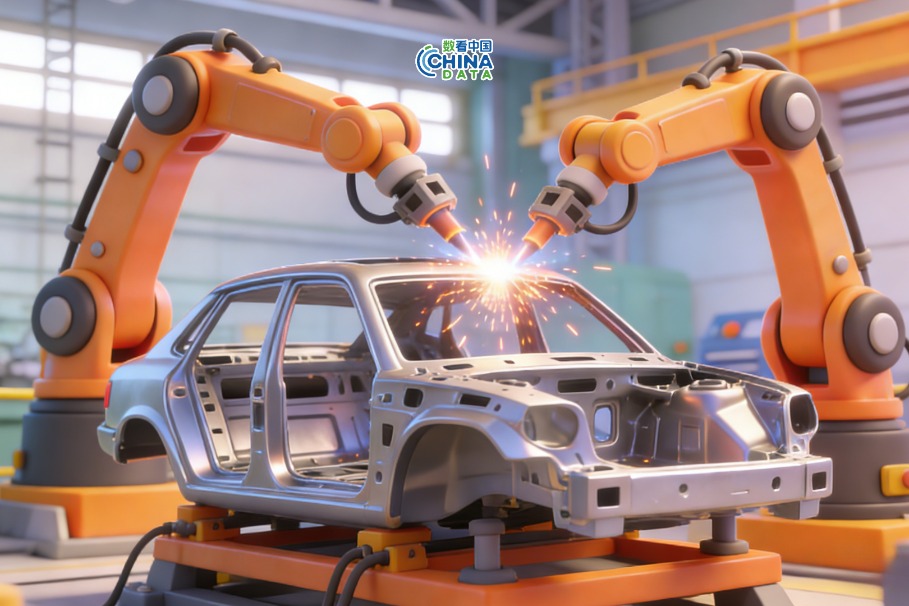

By the end of this year, mass production of the vehicle will start. By utilizing 3D printing technologies, XEV has decreased the plastic parts and number of components in a car from more than 2,000 to 57, while its research and development time will be shortened by two-thirds, said Zhu Li, director of the China 3D-printing Cultural Museum.

Apart from the chassis, seats and glass, all the visible parts of the car are made with 3D printing technology, reducing the investment cost by more than 70 percent in comparison with a traditional vehicle, said Guo.

"The research and development process of a car model conventionally takes between three to five years, but 3D-printed cars like XEV only take between three months to 12 months," said Luo Xiaofan, founder and CEO of Polymaker, a Shanghai-based technology company responsible for R&D of the material for the 3D printed electric vehicle.

Believing the 3D printing technology will become turning point for vehicle manufacturing, Ford launched 3D printing labs as early as the 1980s, and its 3D printer in Michigan plant can manufacture about 20,000 parts every year. Currently, Ford Motor Co is exploring the solution of making large-scale one-piece auto parts, like spoilers, with prototyping, the Michigan-based company said last March.

In addition to the above mentioned features, 3D printing could bring immense benefits for automotive production, including the ability to produce lighter-weight parts that could lead to greater fuel efficiency.

For example, the XEV 3D printed car weighs 450 kilograms, much lower than similar sized vehicles weighing between 1 metric ton and 1.2 tons, thanks to the 3D printing material, said Luo.

Though it is more cost efficient for low-volume production, Ford believes 3D printing is not yet fast enough for high-volume manufacturing.

Goldman Sachs analyst Kota Yuzawa predicted electric vehicles will grow from 1 percent of 2016 global auto sales to 8 percent by 2030, before increasing to nearly one-third of the market share in 2040.