Where the iPhone work went

Updated: 2012-01-29 09:38

By Charles Duhigg and Keith Bradsher (China Daily)

|

||||||||

Tech firms use a global network to get products made

Not long ago, Apple boasted that its products were made in America. Today, almost all of the 70 million iPhones, 30 million iPads and 59 million other products Apple sold last year were manufactured in other countries.

|

|

|

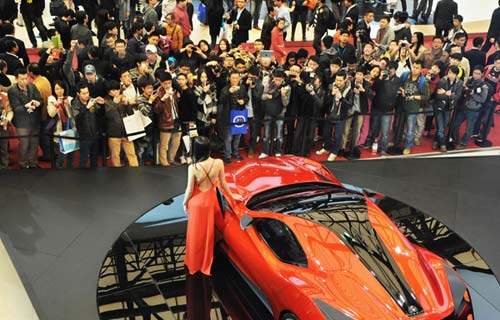

Foxconn Technology, which assembles iPhones in China, was flooded with applicants at a 2010 job fair. [Photo/China Daily] |

Why can't that work come home, President Obama asked Apple's Steven P. Jobs at a dinner in California last February.

"Those jobs aren't coming back," Mr. Jobs reportedly said.

It is not just a matter of wages being lower outside the United States. Rather, Apple's executives believe the vast scale of overseas factories as well as the flexibility, diligence and industrial skills of foreign workers have so outpaced their American counterparts that "Made in the U.S.A." is no longer a viable option for most Apple products.

One former executive described how Apple relied upon a Chinese factory to revamp iPhone manufacturing just weeks before the device was due on shelves. Apple had redesigned the iPhone's screen at the last minute, forcing an assembly line overhaul. New screens began arriving at the plant near midnight.

A foreman roused 8,000 workers inside the company's dormitories, according to the executive. Each employee was given a biscuit and a cup of tea and within half an hour started a 12-hour shift fitting glass screens into beveled frames.

"There's no American plant that can match that," the executive said.

|

|

|

Employees live in dormitories.[Photo/China Daily] |

Apple employs 43,000 people in the United States and 20,000 in other countries. Many more people work for Apple's contractors: an additional 700,000 people engineer, build and assemble iPads, iPhones and Apple's other products. But almost all of them work for companies in Asia, Europe and elsewhere, at factories that almost all electronics designers rely upon to build their wares.

"Apple's an example of why it's so hard to create middle-class jobs in the US now," said Jared Bernstein, who until last year was an economic adviser to the White House. "If it's the pinnacle of capitalism, we should be worried."

Similar stories could be told about other companies in the United States, Europe and elsewhere. Outsourcing has become common in hundreds of industries, including accounting, legal services, banking, textiles, auto manufacturing and pharmaceuticals. But while Apple is far from alone, it offers a window into why the success of some prominent companies has not translated into large numbers of domestic jobs.

"Companies once felt an obligation to support American workers, even when it wasn't the best financial choice," said Betsey Stevenson, the chief economist at the United States Labor Department until last September. "That's disappeared. Profits and efficiency have trumped generosity."

Apple executives say it is a mistake to measure a company's contribution simply by tallying its employees - though they note that Apple employs more workers in the United States than ever before. They say Apple's success has benefited the economy by empowering entrepreneurs and creating jobs at companies like cellular providers and businesses shipping Apple products.

"We don't have an obligation to solve America's problems," a current Apple executive said. "Our only obligation is making the best product possible."

Relief reaches isolated village

Relief reaches isolated village

Rainfall poses new threats to quake-hit region

Rainfall poses new threats to quake-hit region

Funerals begin for Boston bombing victims

Funerals begin for Boston bombing victims

Quake takeaway from China's Air Force

Quake takeaway from China's Air Force

Obama celebrates young inventors at science fair

Obama celebrates young inventors at science fair

Earth Day marked around the world

Earth Day marked around the world

Volunteer team helping students find sense of normalcy

Volunteer team helping students find sense of normalcy

Ethnic groups quick to join rescue efforts

Ethnic groups quick to join rescue efforts

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Health new priority for quake zone

Xi meets US top military officer

Japan's boats driven out of Diaoyu

China mulls online shopping legislation

Bird flu death toll rises to 22

Putin appoints new ambassador to China

Japanese ships blocked from Diaoyu Islands

Inspired by Guan, more Chinese pick up golf

US Weekly

|

|