Chinese factories upgrade to stay competitive globally

Updated: 2015-11-25 11:40

By

HEZI JIANG in Chicago

(China Daily USA)

|

||||||||

In May, China unveiled the national initiative "Made in China 2025", designed to transform the nation from a manufacturing giant of quantity into a world manufacturing power of quality.

"With the slower growth, with the shift in the Chinese economy, the manufacturers have to become more globally competitive, more efficient, more productive," said Tom O'Reilly, Rockwell's president of Asia Pacific.

"Because of the structure of the population through the one-child policy, you see labor costs are rising rapidly because that labor pool cannot grow," said John Watts, marketing director of Asia Pacific. "There's a recognized need from the highest level of government in China that there's a need to up-skill the workforce and become a leading technology provider and a leading manufacturing nation — from big to strong."

Chen said the average age of the 4,000 factory workers at Intco Medical is about 27 to 28, and many are from higher education backgrounds.

"Very few of the workers are doing hard labor. The younger generation doesn't want to do that kind of work," she said.

O'Reilly and Watts acknowledged that Chinese manufacturing has grown significantly over the past two decades.

O'Reilly went to China the first time in the early 1900s, and he remembered automotive manufacturing as "very manual and very primitive".

"If you look now, for example, Shanghai GM or even SAIC, their own brand, ROEWE, those manufacturing plants now are some of the most automated in the world. They have gone from being some of the most primitive, basically a 15-year period, to some of the most automated," he said.

Watts said that nine years ago machine builders in China were all about building the lowest-cost machine they could and positioning themselves as providers of "lower-cost replicas of European or North American machines at reasonable quality".

"Now they are changing their cultures; they are changing their business practices; they are changing their machine designs; they are investing in technology; they are investing in safety; they are building state-of-the-art machines and generating all that innovation within their company.

- Obama, Hollande call for avoiding escalation over Russian warplane downing

- Rights panel presses US over scientists' cases

- Chinese paper company weighs plant in Arkansas

- Chinese factories upgrade to stay competitive globally

- DPRK slams Seoul's firing drill near sea border

- Japanese gov't tight-lipped on shrine explosion

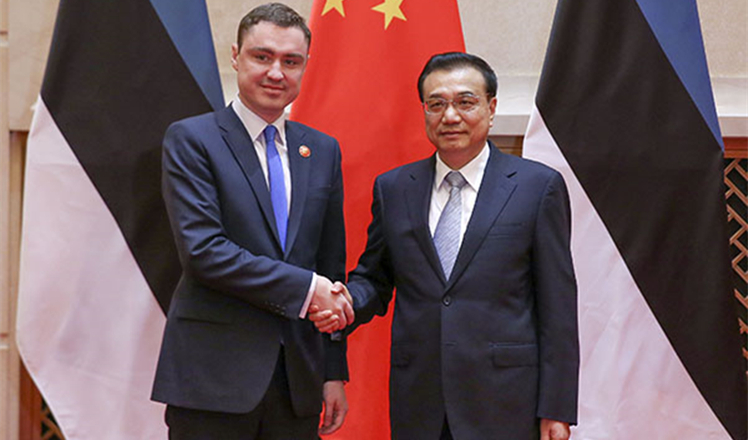

Premier Li's fast-paced diplomacy

Premier Li's fast-paced diplomacy

Obama: US, France stand united against IS, terrorism

Obama: US, France stand united against IS, terrorism

Charming art made from everyday objects

Charming art made from everyday objects

Ukraine sculptors set up workshop in China

Ukraine sculptors set up workshop in China

Billionaire pays for $170m Modigliani with credit card

Billionaire pays for $170m Modigliani with credit card

Crime stoppers meet in DC

Crime stoppers meet in DC

Premier: China ready to advance Baltic Sea high-speed rail project

Premier: China ready to advance Baltic Sea high-speed rail project

Beijing greets the sun after 19 days of gloom

Beijing greets the sun after 19 days of gloom

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Chinese president arrives in Turkey for G20 summit

Islamic State claims responsibility for Paris attacks

Obama, Netanyahu at White House seek to mend US-Israel ties

China, not Canada, is top US trade partner

Tu first Chinese to win Nobel Prize in Medicine

Huntsman says Sino-US relationship needs common goals

Xi pledges $2 billion to help developing countries

Young people from US look forward to Xi's state visit: Survey

US Weekly

|

|