Firm makes more than a scrap of difference to locals

Updated: 2013-10-01 14:31

By Li Lianxing in Lagos, Nigeria (China Daily)

|

||||||||

Keeping pollution to a minimum has been made a top priority for investors

China's spectacular growth over the past 30 years has exacted a heavy toll on its environment. Now the country's leaders are seeking to rebalance the quest for economic success and the need for sustainable development. So as Chinese companies start to move factories to Africa to be closer to raw materials and markets, and to modernize their production methods, they are paying increasing attention to how their moves will affect the environment.

One such company is Hongxing Steel Co Ltd, which is grappling with the problem of pollution from its factory in Lagos, the largest city in the country, even as it keeps its foot on the accelerator to keep up its rapid growth.

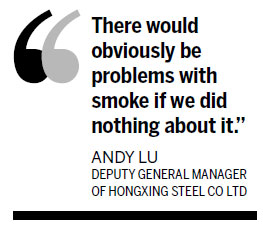

"Most of the scrap iron we collect to make iron rods in Nigeria is of poor quality and contains a lot of oil-based paints and rubber, resulting in heavy smoke when melting those iron materials," says Andy Lu, deputy general manager of the company.

It has never had this problem in China, he says, and faced heavy pressure from Nigerian local authorities and residents soon after its factory opened.

"Our factory is in a busy district of the city with a lot of people living nearby. There would obviously be problems with smoke if we did nothing about it.

"We knew this was an urgent problem that needed to be fixed regardless of how much it cost, otherwise we would have been unable to develop our business here," Lu says. "Our plant and equipment was imported from China and was not designed to handle heavy smoke pollution, so we had to rely on specialists in China."

Those mechanical experts eventually provided the company with a tailor-made solution based on four sets of equipment to minimize smoke.

"The cost was huge for us, 20 million yuan ($3.27 million), almost 20 percent of our total annual profit then," Lu says. "The problems and associated costs are still there when we need to get people over from China and import spare parts to deal with ongoing issues."

Despite those costs, Lu says, if Hongxing Steel is to continue growing in Africa it must continue to spend money on equipment that minimizes pollution.

An official from the local environmental authority, who did not want to be named, says: "Whatever companies produce, environmental protection is the priority because it affects the very basic life of Nigerians and pollution can result in harm that cannot be undone."

It was clear from the start that Hongxing Steel had problems with pollution, she says, but it immediately took steps to reduce it, demonstrating that it cares about the environment.

"It's good for them, too. Once they clean up and keep modernizing they can produce as long as they want."

However, environmental protection standards and policies are beyond Nigeria's area of expertise and are framed using Western guidelines, she says.

"Some of the rules are too strict. I don't think anyone could fully adhere to them under current circumstances, so this is a chance for us to work with these companies to come up with more appropriate rules."

Apart from protecting the environment, Hongxing Steel says its long-term goals in Africa include creating jobs and adapting more to the local market.

"We started our business in Nigeria in 2009 with investment of 60 million yuan and since then we have been dedicated to localizing our company and integrating it into local society," Lu says.

"Production has increased fourfold and we have opened a factory in Benin City (in the south of the country), but the number of our Chinese staff has remained below 30. We have more than 1,000 local staff."

Julius Yakubu, a team leader in the production area, says he used to work for another steel company in the city and joined Hongxing Steel so he could learn more about technology.

"The pay is attractive but, more importantly, I can learn new skills and technologies because they always have new machines in here. I've worked in a steel factory for more than eight years and this place always gives us new things to learn."

Lu says Nigeria's steel production is based on scrap iron rather than iron ore, which is little exploited in the country. Thus collecting scrap iron to turn waste into wealth is also a good way to create jobs in the country.

"We have many agents in the country looking for people to work for us, collecting materials from abandoned cars or other things," he says. "So as our production and raw materials increase, it means the indirect jobs we create grow too."

Joseph Odun, 42, who sells raw materials to Hongxing Steel, says he has more than 100 agents in the southeast of the country collecting scrap iron for him and the number is growing.

"Sometimes demand from the company drops because of mechanical problems with equipment that results in production being suspended, but generally production is growing and we need more raw materials."

lilianxing@chinadaily.com.cn

|

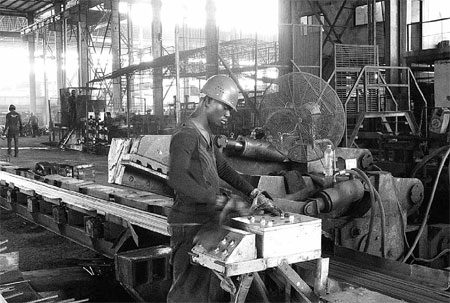

Hongxing Steel says its long-term goals in Africa include creating jobs and adapting more to the local market. Li Lianxing / China Daily |

(China Daily 10/01/2013 page14)

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

US government partial shutdown begins

Pentagon reassures China over India ties

China committed to deepening reform

Chinese embassy in Syria attacked

Li: China confident in meeting economic targets

New FTZ gets a big US bank

China, India join hands on border stability

China issues guidance for government purchases

US Weekly

|

|