JNC: Localization to meet growing demand

Updated: 2013-02-06 07:40

(China Daily)

|

||||||||

After taking over all business of its parent - the Japanese chemicals group Chisso - in April 2011, the newly-formed company JNC is now focused on market expansion for its core product: liquid crystals.

It is also enhancing production and sales of non-woven fabrics, plastic compounds for automobiles, licensing production technology and waste- water treatment. It is in these key areas that JNC intends to strengthen its approach to the Chinese market.

JNC's liquid crystal is made using advanced organic synthesis technology, an innovation that few other manufacturers worldwide can equal. In fact JNC's chief concern in China is assuring steady supply to meet the rapidly expanding demand.

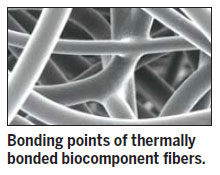

JNC's non-woven fabrics are made from ES fiber combining two types of resin with different melting points. Since the fabric does not use adhesives it is extremely safe for skin. Its main application is in personal hygiene products like diapers.

In Guangzhou, a production facility with an annual capacity of 10,000 tons of ES fiber and 7,200 tons of thru- air non-woven fabrics has already been established. A non-woven fabrics plant with a capacity of 4,800 tons is also operational in Changshu, Jiangsu province. JNC's plans from 2013 onwards include the building of a new ES fiber manufacturing plant in Suzhou.

JNC's plastic compound products are made of long glass-fiber reinforced thermoplastic resin, resulting in a highly rigid and impact-resistant material. To-date, resin has been exported from Japan to make these compounds.

However, continuing strong demand in China has prompted the company to build a plant to produce the resin in Jiangsu. This new plant began operation in autumn of 2012.

JNC first started producing PVC in 1941, and it grew to become the foremost PVC producer in Japan. Though JNC stopped PVC production in 2003, it has licensed suspension PVC technology and vinyl chloride monomer removal technology to companies around the world since the late 1970s. Total capacity of JNC's licensed plants has exceeded 4.6 million tons per year, while capacity of such plants in China has reached 3.72 million tons per year.

In July 2012, JNC granted a PVC technology license to Jinchuan Group in Gansu for its 240,000-ton per year PVC project. JNC's current PVC technology holds many advantages for clients, such as a large number of licensable PVC grades, high-quality PVC products and a low production cost.

For the wastewater treatment industry in China, JNC is employing a bio-reactor system that uses the action of soil-dwelling fungi. The system effectively suppresses the release of unpleasant odors when treating water with high contaminant concentrations. Sludge produced is also recycled to make fertilizers.

JNC's use of innovation in China, coupled with increased local manufacturing of its advanced products, is expected to keep the company well-paced to meet growing demand and sophistication in the market.

http://www.jnc-corp.co.jp/english/index.html

World Eye Reports provided the story

(China Daily 02/06/2013 page7)

In Photos: 7.0-magnitude quake hits Sichuan

In Photos: 7.0-magnitude quake hits Sichuan

Li Na on Time cover, makes influential 100 list

Li Na on Time cover, makes influential 100 list

FBI releases photos of 2 Boston bombings suspects

FBI releases photos of 2 Boston bombings suspects

World's wackiest hairstyles

World's wackiest hairstyles

Sandstorms strike Northwest China

Sandstorms strike Northwest China

Never-seen photos of Madonna on display

Never-seen photos of Madonna on display

H7N9 outbreak linked to waterfowl migration

H7N9 outbreak linked to waterfowl migration

Dozens feared dead in Texas plant blast

Dozens feared dead in Texas plant blast

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Live report: 7.0-magnitude quake hits Sichuan, heavy casualties feared

Boston suspect cornered on boat

Cross-talk artist helps to spread the word

'Green' awareness levels drop in Beijing

Palace Museum spruces up

First couple on Time's list of most influential

H7N9 flu transmission studied

Trading channels 'need to broaden'

US Weekly

|

|