Craftsmen attempt to keep traditional techniques alive

Updated: 2013-06-13 07:36

By Deng Zhangyu (China Daily)

|

||||||||

|

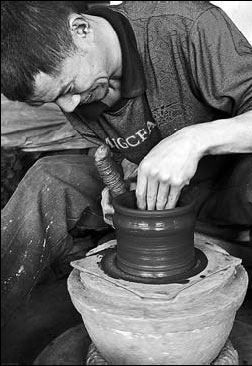

A craftsman at Yingjing kiln works on a potter's wheel at Yingjing, Sichuan province. Zhang Jiantang / For China Daily |

The fire in a kiln of Yingjing county burns up to 1,500 degrees, flames blazing. Inside are rows of pots made of a special kind of clay found only here.

It's the first time the 100-year-old kiln has restarted its fire after the county experienced its worst-ever quake in April.

The quake caused cracks to the walls of the factory. After a simple repair, Zhu Qingping's factory started work again in mid-May.

"The pottery, regardless whether they were finished products or semi-finished ones, were shattered to pieces," says Zhu, the eighth generation to work in his family business.

The county in the western part of Sichuan province has a more than 2,000-year-old history of producing pottery. The traditional techniques of pottery making are still widely used today.

Zhu says all the items in Yingjing are handmade. Most workshops are family-owned. Thus the output is very small.

In total, Zhu's factory produces about 20,000 pieces of pottery a month, most of which are soup pots which are considered less complicated.

Made of a unique type of clay found only in the county, the simple yet ancient pottery produced here is more porous and has a better adsorption rate compared to the purple clay pottery in Yixing, Jiangsu province, for instance.

The white and yellow clay combined with local coal ash are made into silver gray soup tureens, teapots and even artwork. But before the firing process, the items are muted black. That's why they are also called black pottery.

"If you make tea with black teapots, they remain fresh even after half a month in the black teacups. They're extremely breathable," says Zeng Qinghong, whose family has been making black pottery for generations.

During Qingming Festival in April, Zeng sold hundreds of black pottery every day, mostly pots and teapots. But business has been poor since the quake.

"A craftsman makes only one teapot a day. Before the quake, the demand was greater than supply. But now people are afraid of coming here in case there is another killer quake," says Zhu, who owns one of the biggest factories in Yingjing. He has 30 craftsmen at his factory but says hiring skilled craftsmen remains a challenge.

Many people in the mountainous county choose to work in the cities for bigger paychecks so that they can rebuild their houses, instead of remaining in the county to be craftsman, which pays little.

A craftsman makes, on average, 30 pots a day and earns a salary of 2,000 yuan ($320) a month. For those who are skillful enough to make teapots, they earn an extra 1,000 to 2,000 yuan, says Zeng.

"But that's not enough to keep the youngsters here to learn our traditional techniques. Besides they have to sit for a whole day. It's boring for them," says Zeng.

Then why not use machines?

"I want to keep the purity of traditional handicraft. More people now prefer handmade pottery. To some extent, handmade pottery is one of our advantages," says Zeng, who believes in quality over quantity.

(China Daily USA 06/13/2013 page10)

Michelle lays roses at site along Berlin Wall

Michelle lays roses at site along Berlin Wall

Historic space lecture in Tiangong-1 commences

Historic space lecture in Tiangong-1 commences

'Sopranos' Star James Gandolfini dead at 51

'Sopranos' Star James Gandolfini dead at 51

UN: Number of refugees hits 18-year high

UN: Number of refugees hits 18-year high

Slide: Jet exercises from aircraft carrier

Slide: Jet exercises from aircraft carrier

Talks establish fishery hotline

Talks establish fishery hotline

Foreign buyers eye Chinese drones

Foreign buyers eye Chinese drones

UN chief hails China's peacekeepers

UN chief hails China's peacekeepers

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Shenzhou X astronaut gives lecture today

US told to reassess duties on Chinese paper

Chinese seek greater share of satellite market

Russia rejects Obama's nuke cut proposal

US immigration bill sees Senate breakthrough

Brazilian cities revoke fare hikes

Moody's warns on China's local govt debt

Air quality in major cities drops in May

US Weekly

|

|