Latching on to China’s potential

Updated: 2015-11-28 05:34

By YU RAN in Shanghai(China Daily)

|

|||||||||

|

|

Southco's sales in Asia have grown substantially over the past decade, thanks to the vision of its CEO Brian M. McNeill. Provided to China Daily |

When Brian M. McNeill was appointed as the CEO of Southco in 2000, about 80 percent of the company’s sales were from the United States, while Asia accounted for just 3 percent. Today, thanks to his efforts in turning the company into a leading global provider of latches and access hardware in China, sales of Southco’s products in Asia have spiked to 20 percent.

Founded in 1899, Southco initially only manufactured pipes for the oil industry in Pennsylvania. It wasn’t until 1945 that the company rolled out its specialty fastener and latches.

“We had set a goal of manufacturing close to the customer. That was the reason why we came to China and invested in manpower, factories and equipments. We wanted to become a local leader,” said McNeill. “To make parts for the United States and Europe markets is not the reason for us to come to China.”

One of the first steps that McNeill made to achieve this was done 10 years ago when he established Southco Manufacturing and Technology (Shanghai) Co. Ltd, a small 45-staff outfit to focus on the production of plastic products for transportation businesses. Today, the staff numbers have more than tripled to 150 employees who boast extensive networks in areas such as sales, design, manufacturing, distribution, customer service and technical support.

Like most foreign companies entering the Chinese market, Southco had a limited local network and first started selling parts to Western brands manufactured and transported from the US. But McNeill soon realized that this was not a viable long-term solution if the company was to better understand the local market and build its reputation. To do so, the team at Southco Shanghai carried out a series of research projects with potential clients and eventually come to the conclusion that Chinese customers demand quality but at a low cost.

This finding led the team to experiment with all kinds of means to reduce wastage, minimize costs and transform their Chinese factories into some of the most advanced plants that Southco has in the world. The only way to achieve this was through innovation, which was already a core focus in the company.

Southco swiftly moved to upgrade their equipment and introduce new technology to their manufacturing process. In the near future, they will also be introducing robots to their factories to keep up with their innovation drive.

With the aid of technology, Southco has been able to introduce hundreds of new products to the market over the past year, boasting an impressive average output of one and a half products per day. Half of these new products have come out of China.

“We have been forced to invest in technologies for the manufacturing aspect as this will enable us to create our products in the most cost effective way possible as well as eliminate unnecessary labor. This will in turn help raise the wages of the people who are needed to operate the equipment,” said McNeill.

This keen focus on their employees has also been one of the key factors to their success in China. McNeill describes the company culture as one that is a blend of being employee-centric and having the passion to perform.

To ensure that they hired only the best talents, the company went to great lengths to establish relationships with universities in order to attract graduates. It also provides special classes for their newly-hired graduates to gain a holistic understanding of the businesses, from the manufacturing aspect to design and sales. Following the completion of this two-year course, employees can choose to work in whichever department they prefer.

“We need to hire more young engineers and give them hands-on experience so that we can create a pipeline of talent for the company,” explained McNeill.

Furthermore, the company also constantly strives to treat their employees worldwide as equals by adopting a global compensation system where staff from any of their branches and subsidiaries share the same salary structures. According to McNeill, who said that “the commitment to the company is like a marriage”, talent retention is a very integral part of Southco’s culture.

“We want every employee to be a really good fit and ensure that whoever decides to come to Southco will be here for a long time,” he said.

With regard to the future, McNeill believes that Southco still has much to offer to local consumers, especially in this day and age when Chinese brands are slowly but steadily rising in prominence to pose stiff competition to their Western counterparts.

“Made-in-China has a very different meaning today than it had 10 to 20 years ago. Fifteen years from now, I expect that Chinese brands will be manufactured in the US, Europe and many other parts of the world,” said McNeill.

“And this is where we help because Southco is a global company. We can assist customers with design here in China or help advise their factories in countries where we have a presence as well.”

yuran@chinadaily.com.cn

- Britain's Cameron says time to bomb militants in Syria

- Russia accept full suspension from athletics

- Turkish and Russian FMs to meet in Belgrade

- S.Korea, DPRK agree to hold vice ministers' meeting for improved ties

- Avoiding escalation over Russian warplane downing

- Rights panel presses US over scientists' cases

A day in the life of a deliveryman

A day in the life of a deliveryman

Orphanage shows love and compassion across borders

Orphanage shows love and compassion across borders

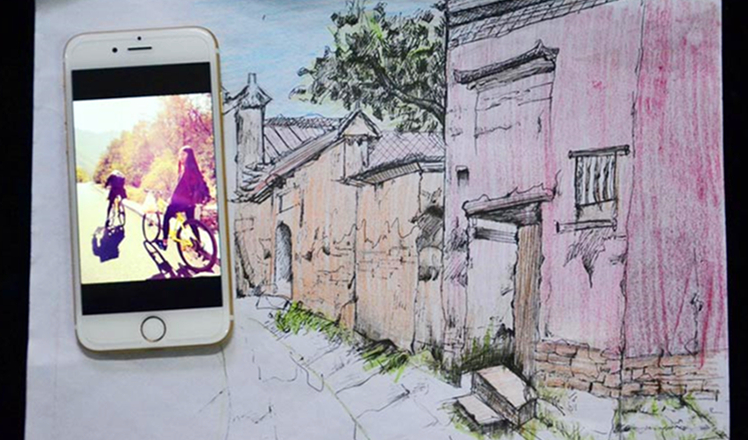

College student paints creative travelogue

College student paints creative travelogue

Macy's Thanksgiving Day Parade colors NYC

Macy's Thanksgiving Day Parade colors NYC

Obama pardons National Thanksgiving Turkey 'Abe'

Obama pardons National Thanksgiving Turkey 'Abe'

Premier road show: Li takes CEE leaders on high-speed train ride

Premier road show: Li takes CEE leaders on high-speed train ride

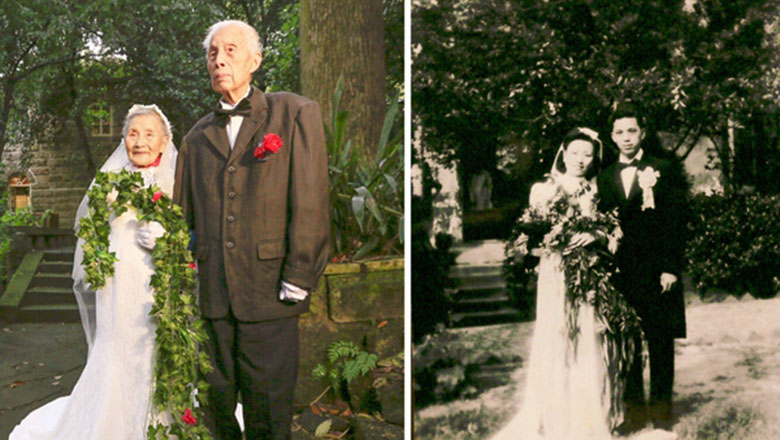

Trending: Love through war and peace

Trending: Love through war and peace

Miss World 2015 to be crowned in Sanya

Miss World 2015 to be crowned in Sanya

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Chinese president arrives in Turkey for G20 summit

Islamic State claims responsibility for Paris attacks

Obama, Netanyahu at White House seek to mend US-Israel ties

China, not Canada, is top US trade partner

Tu first Chinese to win Nobel Prize in Medicine

Huntsman says Sino-US relationship needs common goals

Xi pledges $2 billion to help developing countries

Young people from US look forward to Xi's state visit: Survey

US Weekly

|

|