NZ baby formula to record manufacturing process

Updated: 2013-09-24 23:56

By Zhou Wenting (Xinhua)

|

||||||||

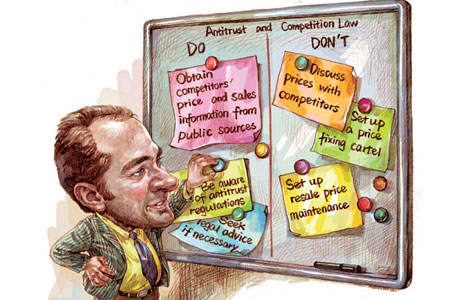

Video recording of the manufacturing process from the pasture to storage will be adopted by some New Zealand baby formula makers to regain the trust of Chinese consumers after the Fonterra safety scare.

Michael Barnett, chairman of the New Zealand Infant Formula Exporters Association, said on Tuesday in Shanghai that the group has reached an agreement, including on a new approach to tracking product sources, with the China Certification and Inspection (Group) Co, a testing agency authenticated by China's General Administration of Quality Supervision, Inspection and Quarantine.

"Our ultimate goal is that consumers can look at a packet of baby formula and find all the traceability by scanning the label," Barnett said.

"Traceability can make consumers more confident of the product quality because they'll know where the ingredients come from and the testing process."

Yang Yi, managing director of the Shanghai branch of CCIC, said the first step is to use video as testimony when the quality of an end product is questioned.

"Some dairy businesses currently show traceability through information collection, including data on various testing reports. What we'll do is to restore the process visually, which is more powerful," said Yang, adding that such video recordings will be available within half a year.

Barnett said the attempt aims to remove the adverse impact caused by anxiety over Fonterra milk powder, which led to four baby formula brands — Dumex, Karicare and Cow & Gate, all three subsidiaries of Danone Group; and Abbott Laboratories —recalling products in China in August.

Alarm bells started ringing on Aug 3 when Fonterra, the world's largest dairy exporter, announced tests had discovered Clostridium botulinum bacteria in whey protein concentrate manufactured at its Hautapu plant in Waikato in May. Food manufacturers use whey protein in baby formula and sports drinks.

The scare turned out to be a false alarm and the Ministry for Primary Industries of New Zealand said on Aug 28 that eventual test results confirmed the germ was not Clostridium botulinum but Clostridium sporogenes, which causes no harm to human health.

The recalls were a precautionary measure to protect consumers to the utmost, said Scott Gallacher, deputy director general of the Ministry for Primary Industries of New Zealand.

"We abided by New Zealand's open and transparent business ethics and finally proved it was safe, but the incident has damaged the flow of New Zealand dairy products into the Chinese market," said Barnett, who declined to give detailed figures.

On Aug 6, China halted imports of whey protein powder and whey protein concentrate produced by Fonterra in New Zealand, and the ban has not been revoked.

"Fonterra is still cooperating with the Chinese government and the reassessment of testing regulations and tracking of the products is going on. It'll speak up after the assessment is over," Barnett said.

The New Zealand Infant Formula Exporters Association, founded in September 2012, has 20 members, which are mainly small and medium-sized enterprises.

"These businesses have committed to develop the China market for years and they value the China-New Zealand partnership and would do nothing that might damage it," Barnett said.

China imported 371,000 metric tons of raw milk powder from New Zealand in the first half of this year, accounting for approximately 83 percent of the country's total milk powder imports, according to the General Administration of Customs.

"As a small nation that relies on exporting food, you can trust that we take product safety extremely serious," New Zealand Prime Minister John Key said in a prerecorded video played at the media briefing.

"I can guarantee the country has world-class testing regimes, regulatory approaches and excellent production systems," he said.

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

BlackBerry agrees to bid to go private

FM: China opposes all forms of terrorism

Microsoft shifts tablet plans for China

GSK's China sales may be down 30% on scandal

China to help deal with chemical weapons

China, Africa 'share destiny'

Maryland, Xi'an seek new link

Trending news across China

US Weekly

|

|