High-end manufacturing holds the key

Updated: 2013-03-01 08:47

By Zheng Yangpeng (China Daily)

|

||||||||

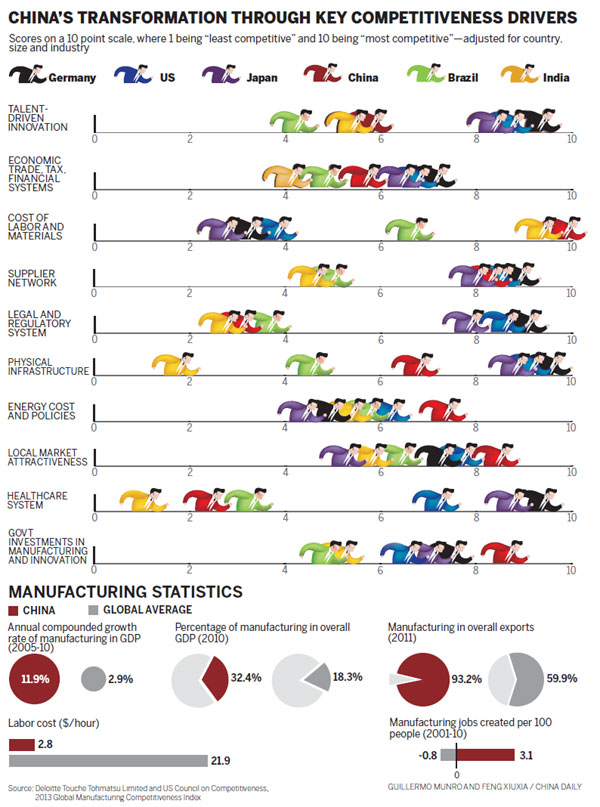

In January, the French tire maker Michelin Group decided to invest $1.5 billion, its largest single investment in China, to open a factory in Shenyang, capital of Northeast Liaoning province.

Asked if rising labor costs were a concern for the factory, Michelin's executives said China's huge market demand is "tempting" enough to offset the impact of a cost rise.

"As one of Michelin Group's most important markets, we will meet the diversified demands of local consumers through our innovative technologies and products, especially in the high-performance sector," says Jean-Dominique Senard, president of Michelin Group.

|

||||

China overtook the US as the world's biggest car market in 2010. In 2012, China's automobile sales rose by 4.3 percent, the lowest growth in several years, amid slowing economic growth and restrictions on auto purchases.

But not all manufacturers have the confidence that growing domestic demand will offset rising labor costs. A report by international accounting firm Grant Thornton in February revealed that 61 percent of the businesses in China cite shortage of general workers as their primary problem, while 55 percent cite a shortage of technical skills as a major concern.

Li Huaying, owner of the Shanghai Litan job agency, says it is becoming increasingly difficult to fill the lower-paying positions, as workers' demands are higher than expectations.

"It is becoming difficult for a company to hire an ordinary worker without any specific skills for a monthly salary of 2,000 yuan, as the salary is deemed to be unacceptable for migrant workers in Shanghai," Li says.

Lu Ming, an economics professor with Shanghai Jiao Tong University, says that what worries him most is that the latest round of wage increases is the result of insufficient labor supply, rather than the result of productivity increases.

"A healthy scenario is that people want to increase their salaries or find a job with stronger fulfillment so that they can go to colleges and get more training. This helps enhance skills and improve productivity," Lu says. "Currently this does not seem to be the case in China."

Zhou, however, says that higher labor costs are a good thing as they create pressure on Chinese manufacturers to improve their efficiency, upgrade their products and move up the value chain. "The truth is that you have to create more value, or else you will die."

For foreign manufacturers who have a huge workforce, rising wages are not necessarily a lead sinker that would threaten their survival, if managed smartly, experts say.

Tan Chow Khong, managing director of AMD Technologies' Suzhou plant and vice-president of the company's manufacturing operations, says his plant has seen the fastest growth in wages among all AMD operations around the world.

"Wage rises and high employee turnout rate did put some pressure on us. But our business is a capital-intensive one and labor cost is showing an increasing trend, which must be offset with productivity gain," says Tan.

Another trend that is slowly shaping among Chinese manufacturers is that many are now setting up offices and shops in developed markets. Communicating directly with local consumers helps them better understand their needs, while an increasing number of mergers and acquisitions have helped them gain access to advanced technology, management and marketing skills.

When asked about the reason for moving his business overseas, Zhang Yu, vice-president of a Guangdong-based audio equipment maker who is now doing business in California, says: "Our sales rose in recent years, but profits dropped significantly. We'll die if we don't expand. We have no choice."

zhengyangpeng@chinadaily.com.cn

(China Daily 03/01/2013 page4)

Li Na on Time cover, makes influential 100 list

Li Na on Time cover, makes influential 100 list

FBI releases photos of 2 Boston bombings suspects

FBI releases photos of 2 Boston bombings suspects

World's wackiest hairstyles

World's wackiest hairstyles

Sandstorms strike Northwest China

Sandstorms strike Northwest China

Never-seen photos of Madonna on display

Never-seen photos of Madonna on display

H7N9 outbreak linked to waterfowl migration

H7N9 outbreak linked to waterfowl migration

Dozens feared dead in Texas plant blast

Dozens feared dead in Texas plant blast

Venezuelan court rules out manual votes counting

Venezuelan court rules out manual votes counting

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Boston bombing suspect reported cornered on boat

7.0-magnitude quake hits Sichuan

Cross-talk artist helps to spread the word

'Green' awareness levels drop in Beijing

Palace Museum spruces up

First couple on Time's list of most influential

H7N9 flu transmission studied

Trading channels 'need to broaden'

US Weekly

|

|