Automation entering new frontier

|

|

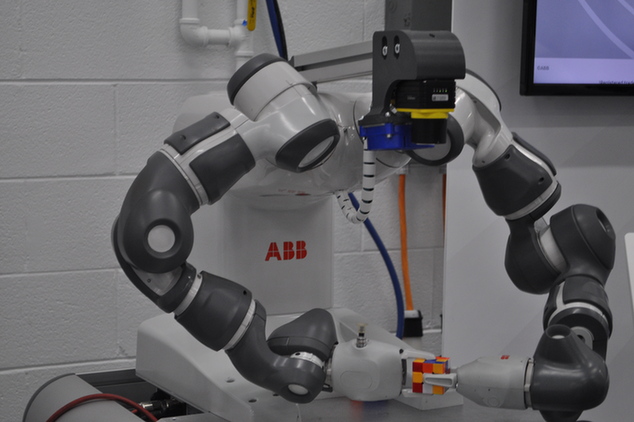

ABB's YuMi® dual-arm industrial robot works a Rubik's Cube at the company's innovation and technology day in its Auburn Hills, Michigan, robotics plant on Wednesday.Photo by Paul Welitzkin for China Daily. |

The development of robots that can perform increasingly sophisticated tasks will accelerate the demand for automation in manufacturing and Swiss engineering company ABB Ltd is geared up to profit from the trend.

Speaking at the company's innovation and technology day ceremonies at ABB's robotics plant in the Detroit suburb of Auburn Hills, Michigan, on Wednesday, CEO Ulrich Spiesshofer said rising demand for robots will not only come from traditional areas like automotive manufacturing, but also in food and beverage production, logistics and pharmaceutical manufacturing.

"Industrial automation is a huge $200 billion market opportunity," said Spiesshofer.

The growing demand from new industry verticals will also mean a rising robotics market in China, where ABB has a work force of about 2,000. Sami Atiya, the president of the robotics and motion division at ABB, said robotics demand in the mainland is being driven by companies in the automotive and consumer electronics sectors and in food and beverage production.

"We are the number one provider in China and that is because we were there early," Atiya said. "The China robotics growth is probably highest in the world."

ABB also produces robots in China. "We export from China and it is a key market for us," said Atiya.

One sector that is experiencing an increase in robotics usage is logistics amid the surge in package shipments from online retailing — think Alibaba in China and Amazon in the US. ABB is developing robots that can label and sort high volumes of packages in various sizes and containers.

Companies like Alibaba and Amazon must deal with the "sheer demand for manpower that is required to cope with the fluctuating demand at a fulfillment center," said Atiya. "There is huge demand when certain seasons occur and then the companies need to ramp down."

The demand for industrial robots is also increasing in the production of food and beverages and pharmaceuticals. As robots become increasingly intuitive and flexible, the machines are able to produce products using a variety of ingredients such as liquids, powders and pills in precise amounts and place them into an assortment of containers at high volumes, ABB said.

Atiya said robotics is helping companies to customize production to produce a limited amount of inventory in a cost effective manner. For one global shoe company, ABB developed a robotic machine that can manufacture one shoe in a certain color, design and size.

"That will allow a lot of smaller companies to expand sales quickly," he said.

The advancing use of robotics and automation also means there will be job displacement and the likelihood that it will take some time to sort out the winners and the losers.

Atiya agreed that while some jobs will be lost, others will be created in the design, development, installation and maintenance of industrial robots.

"Certainly there will be some adjustments in the transition," said Atiya. "But if you look at the countries that have the highest number of robots per manufacturing employees (like Germany, Japan and South Korea), they enjoy a lower unemployment rate than other countries."