From the ground up

Updated: 2012-06-08 10:24

By Wang Chao (China Daily)

|

||||||||

|

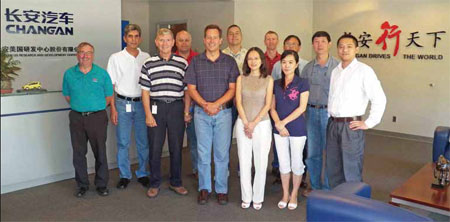

Changan Automobile aims to catch up with international carmakers and last year set up an R&D center in the United States. Provided to China Daily |

Chinese automaker takes 'reverse engineering' approach to design new cars

Nie Zifeng, chairman of the Detroit Chinese Engineers Association, says there is a running joke in the industry about Chinese cars - they look like top makes from a distance, feel like second class inside, and drive like third-class vehicles.

Detroit has been held up as the carmaker's mecca for many Chinese carmakers but the US auto hub could now have a renewed significance for them - to help these brands shed their image as cheap, shabby and unsafe manufacturers.

That is why Changan Automobile Group Co, a major domestic carmaker in China, decided to become the first Chinese carmaker to establish a research and development center in Detroit.

The center, called the Changan US R&D Center Inc, recently celebrated its first anniversary with 22 locally recruited engineers and began to test new types of chassis.

"It's not hard to get geometric parameters from the best cars in the world, but we don't know why they are designed that way. That's what we are doing here," says Su Hong, vice-president of the center.

The center is working on three chassis systems that will be used on three new car models by 2016.

Changan has established joint ventures with Mazda, PSA, Ford and Suzuki in China. Early models under the Changan brands were mostly based on initial joint-venture products and priced low.

"We can never catch up with international carmakers by doing similar styling. It is the function, not the look, that counts for a car," Su says.

But starting from the ground up is not easy. Just one year ago, when Changan rented the 2,200 square meter office belonging to Dow Automotive in Plymouth, a city 32 kilometers from Detroit, there were barely any employees to fill the space.

Over the past 12 months, 22 engineers with an average working experience of 26 years joined the company, in part from the fallout of the financial crisis hitting major US car companies such as GM, Ford and Chrysler.

The US center is part of Changan's grand global R&D center blueprint. Before the center took shape, Changan already had eight R&D locations in five countries - focusing on design in Italy, decoration in Japan, engine, transmission in the United Kingdom, and now chassis work in the United States. It also has five R&D centers in China.

"Six years ago, when we opened the styling center in Italy, we didn't even know how to make a car look good. But now we are working on the chassis, the most sophisticated part of a car," Su says.

Graig Sutton, manager of suspension and steering at the Changan US R&D Center, says "reverse engineering" is the right option for late-comers like Changan. Sutton worked 21 years in the automobile industry before joining Changan last summer.

"You get started from the established model, you do tests, then you can understand a little bit of how it works. If you do enough of that, or benchmarking, you can create your own standards.

"Here we do benchmarking even if the company is well-established, because engineers in different companies have different ideas. We need to learn from each other."

Sutton says there are two approaches for Chinese auto companies to catch up with their Western counterparts - through setting up local offices in the technology centers such as Detroit and by finding the resources here, picking out high-level talent and bringing them back to China.

"But in my opinion, the approach Changan took is a quicker way to get there: We provide an immediate team here that is able to design and develop vehicles," he says.

For the past 10 years, Nie has also seen Chinese carmakers come and go in the US, each eyeing the then largest automobile market in the world, but Changan is the only one that established a branch office here.

"Some auto parts companies came here and became suppliers of Ford, GM, or Chrysler. They earn decent money, but Changan thinks bigger than that. It came here for talent and the technology, and then applies these technologies on domestic cars."

Changan learned lessons from dozens of Chinese auto companies that partnered with foreign brands and they expect to tap the Chinese market with Western technologies.

After decades of involvement in joint ventures, Chinese carmakers have seen the country become the largest overseas market for many Western auto companies such as GM and Volkswagen. But their dream of a "market for technology" is still considered remote.

"Chinese companies have to own their core technologies to gain respect from competitors, be it for the chassis, engine, or transmission," Nie says. "The progress Changan is making is not very fast, but it is good enough."

According to Changan's plan, the US center should be able to provide spare parts for domestic models in four to five years.

But quality control now is the biggest challenge for Changan, Su says.

"We can acquire technologies or hire senior engineers from the US, but maintaining a consistent quality is the major problem now," he says.

To address this issue, Changan is conducting frequent collision tests and collecting data to correct possible errors.

For the same reason, the company prefers to take it slow to enter mature markets such as the US and Europe, because "it's better to have no impression than a bad one".

"If quality is bad, once we debut in these markets, the image of Chinese cars will be damaged," Su adds.

Mergers and acquisitions are also not in its near future. Gu Jianmin, deputy general manager of Changan US R&D Center, says Changan is very cautious in doing overseas M&A because the approach does not necessarily include intellectual property.

Once Changan owns the technology, logistics and distributions networks will be easy to catch up with, Su says. "But the engine, power train and chassis form the foundation of a strong auto company. We have to have something solid to say of our company."

wangchao@chinadaily.com.cn

Relief reaches isolated village

Relief reaches isolated village

Rainfall poses new threats to quake-hit region

Rainfall poses new threats to quake-hit region

Funerals begin for Boston bombing victims

Funerals begin for Boston bombing victims

Quake takeaway from China's Air Force

Quake takeaway from China's Air Force

Obama celebrates young inventors at science fair

Obama celebrates young inventors at science fair

Earth Day marked around the world

Earth Day marked around the world

Volunteer team helping students find sense of normalcy

Volunteer team helping students find sense of normalcy

Ethnic groups quick to join rescue efforts

Ethnic groups quick to join rescue efforts

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Chinese fleet drives out Japan's boats from Diaoyu

Health new priority for quake zone

Inspired by Guan, more Chinese pick up golf

Russia criticizes US reports on human rights

China, ROK criticize visits to shrine

Sino-US shared interests emphasized

China 'aims to share its dream with world'

Chinese president appoints 5 new ambassadors

US Weekly

|

|