There's gold in them thar slag heaps

Updated: 2012-07-27 07:33

By Jonathan Stefonek (China Daily)

|

||||||||

|

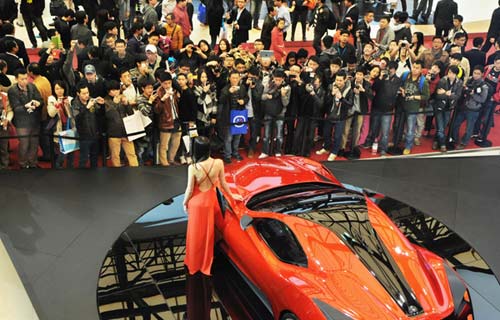

Dan Attorre, Harsco's president of Asia-Pacific operations, brings the company's environmental services to China. Provided to China Daily |

US company joins with Chinese in providing a clean, green solution to a difficult and dirty problem

As speculation mounted last week about a new Chinese government stimulus, industrial stocks rose, a welcome sign for the beleaguered steel industry, which has been finding it increasingly difficult to turn a profit.

One of those that would have been feeling the pinch is the New York-listed Harsco Corp. All the same, it has been expanding its steel operations in China in the past year, including signing two contracts valued at more than $800 million.

The first of the projects, with Taiyuan Iron and Steel Group Co Ltd, broke ground in November.

"It is, indeed, a good representation of how Harsco Metals and Minerals' future business model will operate," Galdino Claro, executive vice-president and group CEO of Harsco Metals and Minerals said at a conference in December.

"TISCO is a joint venture. Call it TISCO-Harsco Technology Company."

Then on June 20 the company announced a 20-year, $375 million deal with Tangshan Steel Co Ltd, a subsidiary of Hebei Iron and Steel Group Co Ltd.

Harsco, an industrial services company based outside Harrisburg, Pennsylvania, has been thriving by offering to clean up the dirty work of steel production, in particular slag.

"You can't make steel without slag and you don't make slag without steel," says Tom Danjczek, president of the Steel Manufacturers Association, which consists of 36 North American steel producers.

Slag is a combination of non-metal waste steel that is too small to be properly processed. If metal is broken down beyond a certain size and is then put into a furnace heated to about 540 C, it does not melt, but destabilizes and turns into a puff of intense lost energy.

Harsco's business is in rescuing all those otherwise unstable particles and putting them back into the process. What is left after that can still be put to use.

Dan Attorre, Harsco's president of Asia-Pacific operations, says that what remains is then turned into environmentally friendly coke - coal that is burned to smelt iron into steel. If Harsco has its way, the resulting carbon will be put to good use.

"For the TISCO project we emphasize zero discharge," says Shan Dejun, the managing director of Harsco. "So we'll eliminate the need for industrial landfills."

Without a recycling process like the one Harsco provides, there are few workable options of what can be done with the waste.

"At some steel mills it resides on site," Attorre says. "It just sits there."

Danjczek says that in the United States the government treats slag as a commodity.

"Blast furnace slag has very low oxide levels, so it's used on things like roadways and sub-roadway bases because it doesn't expand. Another place slag is used is in the making of cement."

Harsco's environmental services appear to have the ideal market in China, whose government lists food security and environmental protection among its priorities. Shan, whose duties include government liaison, says: "Protecting the environment is something that's extremely important for China."

Shan regards the Tangshan Steel plant as a model of clean production. "You don't see smoke, you don't see anything. It's like a park."

When Claro said TISCO would be a model for the future, it was not simply a reference to the tasks of re-use and waste reduction. The TISCO and Tangshan operations are both joint ventures.

Even though Attorre is an executive and representative of a company in America's steel belt, you would hardly guess it from the way he speaks.

"I was originally born in the United Kingdom, half Italian, half English, but lived in the States, lived in Europe, all working for Harsco. I spent the last four years in Australia, and now in Beijing. That's part of that globalization."

The company operates by the dictum "globally operated, locally managed", extending across 180 locations in 40 countries.

"In each country that we operate in, we want to be a local company. We want as much as possible to localize the management."

But to achieve this in China has required more than a good pitch and a positive philosophy.

Harsco first brought slag processing technology to the country 11 years ago, with Tangshan as one of the first customers, says Yu Yong, chairman of Tangshan Steel. Although not the biggest partner, Yu says, Harsco is one of the most valuable.

"Not only because of their technology, but also because of their attitude, with the respect I got from them."

However, no amount of respect will change the fact that the price of hot-rolled steel has fallen 17 percent in the past year and that on July 13 Bloomberg news reported that the price was down for the 13th consecutive week.

Still, Tangshan and TISCO have expanded their deals with Harsco over 20 years and 25 years respectively. For its part, Harsco is reported to have had a lack of cash on hand, in great part due to large sums being spent on expanding in Asia recently, reducing profit. In the past year its stock price has been decidedly soft.

These contracts, as Shan Dejun sees it, puts Harsco in a position to be less concerned with short-term returns.

"You can spread the return over a much longer period, so that in any particular year the pressure on the return is not so big."

Danjczek, a former steel mill manager, says: "There are times that we have more of an inventory, there are times when we have less of an inventory."

The market for slag is fickle, he says.

"It is very price sensitive to supply and demand."

In March, Baosteel received approval to build an $11 billion plant in Guangdong, but on condition that production of an equal or greater value be eliminated from other plants.

"There will be an impact based on the policies of the government," Yu says.

But there is optimism that this policy of reducing steel production will not hurt Harsco or Tangshan in the long term.

"Yes, it has been the policy, but the government has not been successful in closing those inefficient steel mills," Shan says. "The bigger ones - those SOEs - are good. It's the smaller ones ... they care more, probably, about making money."

Harsco will carry on with TISCO and Tangshan with plans for cleaner, more efficient processes over the next 25 years. As for industry trends, Shan says that is something the Chinese government will have to bring under control.

China Daily

(China Daily 07/27/2012 page15)

Relief reaches isolated village

Relief reaches isolated village

Rainfall poses new threats to quake-hit region

Rainfall poses new threats to quake-hit region

Funerals begin for Boston bombing victims

Funerals begin for Boston bombing victims

Quake takeaway from China's Air Force

Quake takeaway from China's Air Force

Obama celebrates young inventors at science fair

Obama celebrates young inventors at science fair

Earth Day marked around the world

Earth Day marked around the world

Volunteer team helping students find sense of normalcy

Volunteer team helping students find sense of normalcy

Ethnic groups quick to join rescue efforts

Ethnic groups quick to join rescue efforts

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Chinese fleet drives out Japan's boats from Diaoyu

Health new priority for quake zone

Inspired by Guan, more Chinese pick up golf

Russia criticizes US reports on human rights

China, ROK criticize visits to shrine

Sino-US shared interests emphasized

China 'aims to share its dream with world'

Chinese president appoints 5 new ambassadors

US Weekly

|

|