An emperor's lessons in management

Updated: 2012-12-14 08:44

By Marcos Martinon-Torres (China Daily)

|

||||||||

Another reason to be awed by the Terracotta Warriors

'And they did all of this over 2,000 years ago." Whenever I visit Xi'an's Terracotta Warriors, I hear many a keen tourist making a remark that many of us have made before. It seems as if our admiration toward the beauty and technological sophistication of any human creation grows exponentially with the age of whatever we are observing. The mausoleum of China's first emperor, with its colossal pyramid, its numerous accessory constructions, and the thousands of heavily armed terracotta warriors that have made it so famous, is a prime example of a big handful of World Heritage sites that elicit such impressions.

Implicit in these sorts of exclamations is the assumption that things were harder to do in the past - and, by implication, that we are smarter than our forebears. The inexorable progress of science and technology means that life is more comfortable today, and problems are easier to solve - or are they?

In some ways, when we make such observations we seem to be ignoring that the engineering feats of ancient civilizations are more the norm than the exception. We have the pyramids of Egypt and Mesoamerica, the Great Wall of China, the iron from sub-Saharan Africa, or Stonehenge in Britain, to name but a few.

Since 2006 I have been working with a team of Chinese and Western researchers on a project that seeks to explain how the Terracotta Warriors were built. Trying to go beyond the superficial awe of wonder, we have been trying to reconstruct the crafting methods and logistical organization that enabled the construction of this titanic monument in the context of the emerging imperial system.

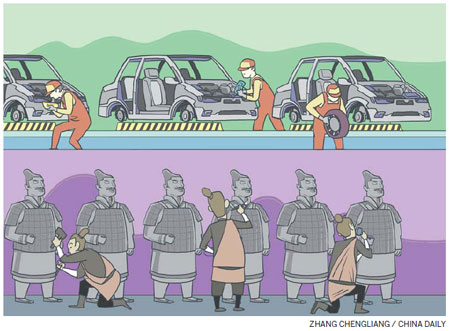

In a recent article in the Journal of Archaeological Method and Theory, we suggested that the labor force engaged in this enterprise, possibly hundreds of thousands of individuals, was organized as a network of relatively small and versatile production cells that worked in parallel. We ventured into identifying similarities between this production model and the organizational system now employed in the factories of Toyota, the world's largest carmaker.

Carrying out the reverse engineering of the Terracotta Warriors to arrive at this conclusion was not a straightforward process. Rather than looking at the warriors themselves, we started by focusing on the infinitude of bronze weapons recovered with them, including hundreds of swords, lances, spears, halberds, ceremonial weapons, and as many as 40,000 arrowheads ready to be used with crossbows.

We carried out metrical studies, chemical and structural analyses and spatial modeling of vast amounts of data. Trying to minimize the risk of damaging any of these artifacts, we had to be creative in adapting methods for our purposes.

For example, for our chemical analyses we employed portable X-ray fluorescence spectrometers, which are more commonly used for mining prospecting or environmental monitoring. Borrowing the polymer putty used by dentists to take teeth impressions, we created accurate moulds of the weapons' surfaces that could be examined under a scanning electron microscope. This examination revealed parallel, microscopic scratches on the blades, indicating that each of them had been sharpened on a rotary polishing wheel, the earliest example of this technology, applied here on an industrial scale.

Perhaps more interestingly, our study showed that each crossbowman's quiver-full of 100 arrows had been individually produced and delivered to the terracotta army pit as a complete set. For each set, all the bronze heads and tangs (and, by extension, the bamboo shafts and feathers, even if these have mostly perished) had been made together with a single batch of bronze, without any mixing of batches between quivers.

The implication of this find is that, rather than a single and enormous line of production, there were several production cells, each with all the raw materials, tools and knowledge required to work in parallel and produce complete multi-component artifacts. The clustered spatial distribution of the different batches of these and other weapons across the pit also indicates that the site was probably divided into "work areas" that were assigned to different groups of semi-autonomous laborers.

This is where the comparison with Toyota comes in. When we think of highly standardized, mass-produced, multi-component items, be they cars or terracotta warriors with their weapons, we tend to imagine a large production and assembly chain, with specialized units sometimes working in different locations. Different parts then join one another in a mechanized assembly line.

Toyota revolutionized car-making in the 1960s with an alternative logistical model structured in small cells of engineers who were on average more highly skilled, more autonomous, and ready to undertake any task as needed. Each cell is capable of making any car model more or less independently. This production system, also known as "just in time" (cars are only produced where and when there is an order in place), has allowed Toyota to be much more adaptable to market fluctuations, and less susceptible to the knock-on effects caused by a breakdown in a given factory.

At the first emperor's mausoleum there was no market to adapt to, but there was a gigantic project of unpredictable evolution. Since nobody had tried to build a terracotta army before, there was no way of accurately predicting the number of items needed or the time it would take to produce them. Having a versatile workforce divided in cells capable of producing quiver-fulls of arrows or swords as needed, depending on the progression of the works, would increase efficiency and minimize the risks of a single delay stalling the whole enterprise.

This ingenious labor organization model had to be used in combination with a rigorous quality-control system that ensured that the same standards were kept across the different production units. Emperor Qin Shihuang (259-210 BC), a ruler who had standardized the legal system, script, units of measurement and currency, would not allow unnecessary variability in the weapons of the warriors meant to protect him in his afterlife. Some of the larger weapons bear chiseled inscriptions that record up to four levels of hierarchical supervision from various foremen to the individual workers who made them. This registration would make it easier to identify those responsible for any errors or imperfections.

The system worked remarkably well: our painstaking measurements of 1,600 arrows showed that the coefficients of variation across the collection were systematically smaller than what our eye can discern. In other words, based on our sample, all 40,000 arrows (and the many more thousands still buried) can be said to be visually identical to one another.

Archaeologists are often asked what lessons we can learn from whatever discoveries we make. While it would be hard to agree today with most of the first emperor's policies, it might be worth highlighting that he maximized efficiency by investing in the cross-training of his workforce, rather than using laborers as specialized machines. At a more general level, this project, which continues, may serve as a reminder that we, in the present, keep reinventing the wheel. Next time that you are awed by a construction made by ancient people, perhaps you should not be so fascinated by the fact that they had technical knowledge, but by how they used it.

The author is a senior lecturer in archaeological science, UCL Institute of Archaeology. The views do not necessarily reflect those of China Daily.

(China Daily 12/14/2012 page9)

Relief reaches isolated village

Relief reaches isolated village

Rainfall poses new threats to quake-hit region

Rainfall poses new threats to quake-hit region

Funerals begin for Boston bombing victims

Funerals begin for Boston bombing victims

Quake takeaway from China's Air Force

Quake takeaway from China's Air Force

Obama celebrates young inventors at science fair

Obama celebrates young inventors at science fair

Earth Day marked around the world

Earth Day marked around the world

Volunteer team helping students find sense of normalcy

Volunteer team helping students find sense of normalcy

Ethnic groups quick to join rescue efforts

Ethnic groups quick to join rescue efforts

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Chinese fleet drives out Japan's boats from Diaoyu

Health new priority for quake zone

Inspired by Guan, more Chinese pick up golf

Russia criticizes US reports on human rights

China, ROK criticize visits to shrine

Sino-US shared interests emphasized

China 'aims to share its dream with world'

Chinese president appoints 5 new ambassadors

US Weekly

|

|