Yuhuang Chemical executes an ambitious plan

Updated: 2015-03-06 11:41

By May Zhou in Houston(China Daily USA)

|

||||||||

|

|

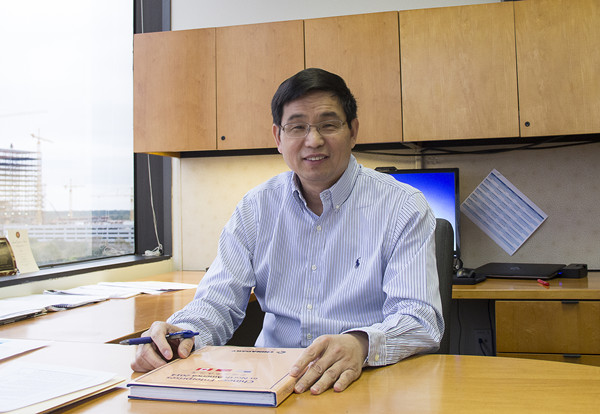

Charlie Yao, CEO of Yuhuang Chemical, Inc talks about his ambitious plan to build a $1 billion methanol plant in four years. May Zhou / China Daily |

Yuhuang Chemical - a US subsidiary of Shangdong Yuhuang Chemical - started its venture in the US with an ambitious plan: build a $1.85 billion methanol complex on 1,200 acres of farm land in St James Parish, Louisiana. It's by far the largest green field investment in methanol by a Chinese company in the US.

"We are trying to complete the first phase of the industrial complex in 2017 with an initial production capacity of 1.7 million tons of methanol a year," said Charlie Yao, CEO of Yuhuang. "Normally, similar projects require six years, we are aiming for a timetable of four years."

Shangdong Yuhuang Chemical Company (SYCC), established in 1986, had humble beginnings. It started out as a small private company with $10,000 in assets. After numerous restructurings, mergers and acquisitions, it has developed into a large privately owned corporation with 13 subsidiaries, more than 5,500 employees, and is ranked the 25th among Chinese chemical companies and 456th among China's top 500 companies overall.

SYCC has established a sales network in more than 20 provinces in China and other countries, including the US, Italy, the Netherlands, South Africa, Brazil and a few Southeast nations. Its 2013 revenue reached $4.27 billion and the group is aiming to increase its annual revenue to $13 billion by 2016.

Wang Jinshu, chairman of SYCC, has become a legendary figure for both his business success as well as his practice of social responsibility. In 2010, he used personal funds of $92 million to build houses for more than 660 families in his home village. Under his guidance, his company has contributed about $13 million to charity and public causes over the years.

A former general manager at Shell recruited by Wang, Yao said the Yuhuang project is a perfect fit for him. His experience at Shell made him a perfect candidate for the ambitious project.

Yao started to work at Shell in 1990 and moved around inside the company. In more than 20 years, he worked in technology, sales, marketing, management, strategy and capital development. Before leaving Shell for Yuhuang, Yao was in charge of Shell's catalyst global supply chain, overseeing four global customer service centers, production planning for four plants and a logistics group.

With well-rounded experience in almost all the aspects of the industry, Yao was chosen by Wang to head the project.

As a first generation immigrant holding such a high position at Shell, Yao was not without hesitation.

"It took me half a year to make the decision to jump ship because I had a lot to give up," he said. "However, what Yuhuang offered me was a once-in-a-lifetime opportunity and challenge: I was given over a billion dollars to start a project from scratch."

Fortunately, Wang and Yao were able to build a strong personal rapport, and Wang's complete trust and confidence in Yao eventually won him over.

"Once Chairman Wang decided to put me in charge, he left all decisions to me without question," Yao said. "He didn't see the site we're using until a few months after the transaction went through. That says a lot."

Officially assuming the role of Yuhuang CEO in April of 2014, Yao immediately began to tackle the daunting tasks of a startup company. "I needed to develop the project, build a business, and build a company," he said.

Yao was quick to action. After considering all the factors, he vetoed SYCC's original plan to build the complex in Texas and opted for the current location of St James Parish of Louisiana on Mississippi River. The official announcement was made in July 2014, three months after Yao took the reins.

"Compared to Texas, Louisiana had cheaper and more readily available green fields, the state government offered better incentives and it also offered the ideal location with easy access to waterway, railroad and ocean transportation," Yao explained.

To take advantage of Houston's excellent and readily available talent in the industry, Yao kept Yuhuang's headquarters and operations there.

To expedite the project, Yao hired China Huangqiu Contracting and Engineering Corporation (HQC) and Technip to do the engineering design with technology bought from Germany for the complex.

The first phase of the project will cost between $900 million to $1 billion. The main design is scheduled to be completed by the end of 2015 and construction is set to begin this summer, according to Yao. When the first phase is completed, the St James plant will have about 200 employees.

After the first methanol plant is completed, Yuhuang will build a second $500 million methanol plant and reach an annual capacity of 3.3 million tons per year of methanol.

The third phase will include a methanol derivatives plant producing intermediate chemicals. Eventually, the complex will employ about 400 people.

It is projected that about 20 to 30 percent of the methanol will be shipped by river and railroad and sold to North American customers. The remaining 70 to 80 percent will be exported by ocean. Roughly 15 to 25 percent will used by SYCC in China.

Yao is confident the project will pay off. Methanol is a widely used for a variety of products. Global demand has been growing and is projected to continue to grow at 8 percent each year.

"That means the industry can absorb an extra two to three world class production facilities a year," said Yao.

Yao had overseen projects of similar size at Shell, but he finds this is much more challenging, especially in terms of human resources.

"It's very easy to quickly put a team together from its available personnel at Shell, with Yuhuang, I have to look for talent not that readily available. So far, this has been the biggest challenge," said Yao.

Currently, Yuhuang is employing a little more than 30 people - 14 of the workers are borrowed from HQC and Worley Parson, with more than half belonging to the team built by Yao himself. As the project progresses, Yao expects the Houston corporate office will have roughly 50 employees to run the operation.

mayzhou@chinadailyusa.com

Obama look-alike lands a movie role

Obama look-alike lands a movie role

The world in photos: Sept 14-20

The world in photos: Sept 14-20

Zhejiang's Zhoushan in full swing for sand sculpture festival

Zhejiang's Zhoushan in full swing for sand sculpture festival

Stars arrive at the 67th Primetime Emmy Awards

Stars arrive at the 67th Primetime Emmy Awards

Top 15 Chinese CEOs to attend US roundtable during Xi's visit

Top 15 Chinese CEOs to attend US roundtable during Xi's visit

Across America over the week (Sept 12-18)

Across America over the week (Sept 12-18)

House showcasing Sino-American friendship open

House showcasing Sino-American friendship open

Top 10 M&A deals between China and US in 2015

Top 10 M&A deals between China and US in 2015

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Young people from US look forward to Xi's state visit: Survey

US to accept more refugees than planned

Li calls on State-owned firms to tap more global markets

Apple's iOS App Store suffers first major attack

Japan enacts new security laws to overturn postwar pacifism

Court catalogs schools' violent crimes

'Beauty of Beijing's alleys akin to a wise, old person'

China makes progress fighting domestic, international cyber crime

US Weekly

|

|