Stars and gripes but flag issue symbolizes partnership

Updated: 2012-08-02 08:29

By Peng Yining (China Daily)

|

||||||||

|

|

Song Hongmin stitching a 2.85 by 1.92 meter US flag. She has been working at Beijing Jinggong Red Flag Factory Co for 10 years, earning 2,000 yuan ($313) a month. Photos by Kuang Linhua / for China Daily |

Age of globalization means getting the best deal, Peng Yining reoports.

Every morning for the past 20 years, Karyn Abe has run the Stars and Stripes up the flagpole in her garden. Every evening, the flag is lowered and stored away, ready for use the next day.

The 68-year-old resident of Hawaii flies the 1.2 by 1.8 meter national emblem to show her allegiance to her country. But for Abe, and many other US citizens, the flag's provenance is as important as the ideals it embodies.

When she learned earlier this month that most US flags sold in the country are made in China, she checked the packaging in which her flag came.

"Thank goodness. My flag was made in the United States!" she said. "It seems a shame to outsource such an American-based thing as our own flag."

And it's not just Chinese-made flags. The matching blazers and uniforms that members of Team USA wore at the opening ceremony of the 2012 London Olympic Games caused an uproar. They, too, were made in China.

|

The flames were fanned by politicians, such as Senate Majority Leader Harry Reid, who said the uniforms - designed by the US couturier Ralph Lauren, but outsourced to China - should have been put in a pile and torched.

The world economy is characterized by a high degree of globalization. Companies export finished goods around the planet and source intermediate input from suppliers located in any number of countries, said Wang Zihong, director of the economics office of the Institute of American Studies at the Chinese Academy of Social Sciences.

"Manufacturing job losses are partly a result of the economic model in the US," he said. "People in the United States certainly have the right to complain about foreign-made flags and uniforms, but that won't change the economic structure, because the US also benefits from global production networks."

The issue of flags and Olympic uniforms is not an important one in terms of Sino-US economic relations, according to Dwight H. Perkins, professor of political science at Harvard Kennedy School in Massachusetts. Perkins said politicians like to stir up nationalist sentiment occasionally and the US flag and Olympic uniforms have a symbolic value in that regard.

For some, it's more basic than that. "No one in America tells you to fly the flag. It's just something that's done out of a feeling of patriotism, love of country and all it stands for. It just makes me feel good," said Abe.

"More specifically, with the flags and uniforms, it's a matter of American pride," she said. "The flag is the very symbol of our country, the Olympic uniform is the symbol of the aspirations America has for its athletes. I would hope that at least these two things, the flag and the Olympic uniforms, could be made entirely in America."

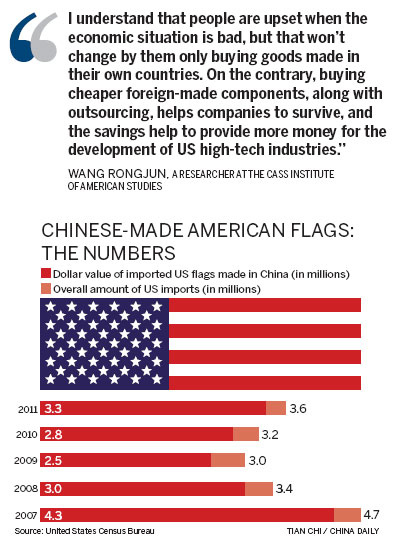

The US imported $3.6 million worth of flags in 2011. Around $3.3 million of that sum went to Chinese manufacturers, according to a report released by the US Department of Commerce in May.

Left in the lurch

In a dim workshop at Beijing Jinggong Red Flag Factory Co, one of China's largest manufacturers of flags, dozens of workers stitch flags and banners. The fruits of their labors fly over Tian'anmen Square and were present in the stadiums during the 2008 Beijing Olympic Games.

Song Hongmin doesn't speak English, has never been to the United States, and doesn't know how many stars are featured on Old Glory, as the US flag is affectionately known. But the 31-year-old uses her sewing machine to stitch the four sides of a 2.85 by 1.92 meter US flag - roughly the size of one and a half double beds - in less than 100 seconds.

Song has been working at the factory for 10 years, earning 2,000 yuan ($313) a month.

"Flag manufacturing is a tough work, but we are lucky that we still have work to do," said Bai Zhiyue, the factory manager, who has seen the company's exports decline sharply as a result of the global economic downturn. "I believe a lot of smaller manufacturers won't make it to the end of the year. By then, lots of Chinese workers will be left in the lurch," he said.

In order to survive, Chinese-made products must improve, moving up the scale from "cheap" to "cheap, but high quality", according to Bai.

Beijing Jinggong has developed a new waterproof material. To demonstrate, Bai took a piece of fabric and poured water over it. The drops rolled across the surface like rain on a lotus leaf as he explained how the new material will soon be used to make flags destined for export, allowing them to fly proudly on rain-swept days instead of becoming sodden and hanging limply.

Global networks

"As the world's largest economy, the US is able to affect the speed and character of the globalization process itself, while many countries can only react to the process," said Wang.

Worldwide production networks are an important aspect of the global economy. Chinese-made flags and clothing are considerably less expensive than their foreign counterparts, so US customers gain from the availability of cheaper products, according to the researcher.

Abe's flag was made by Valley Forge Flag Co of Pennsylvania, one of the top providers of flags and related products to the US government, and cost around $10. A Chinese-made flag of the same size and made from the same poly-cotton material, costs less than $8, according to Shanghai Tongjie Image Production Co, one of the oldest and largest flag manufacturers in Shanghai, whose products are mainly exported to the US. If a different material had been used, the price could be lower than $1.50, according to Shanghai Tongjie's sales staff.

On the packaging of Abe's flag, a small sticker reads "Flag woven, printed and sewn in the USA. Other components made in China."

"It seems you can't get away from buying Chinese-made products," she said. "By importing so much from China, we are naturally taking jobs away from Americans. This is becoming more and more important as our economy sinks." That message was given a deeper resonance by figures showing that the US unemployment rate stood at 8.2 percent in June.

As global economic activity declines, outsourcing - the practice of companies manufacturing their products outside their own countries - has become a target for critics of globalization, who argue that it's responsible for job losses in the domestic manufacturing sector.

"I understand that people are upset when the economic situation is bad, but that won't change by them only buying goods made in their own countries. On the contrary, buying cheaper foreign-made components, along with outsourcing, helps companies to survive, and the savings help to provide more money for the development of US high-tech industries," said Wang Rongjun, who also works as a researcher at the CASS Institute of American Studies.

"As an irreversible trend, global production sharing will, and should, continue," he said, adding that he hopes the US government will not allow the specter of rising unemployment to push it into trade protectionism. "If that happened, both the US and Chinese economies would be damaged."

As the costs of labor and raw materials rise, even Chinese manufacturing jobs are being moved overseas. Xie Weijie, who used to run a factory in Shenzhen, Guangdong province, that supplied digital components for Japanese camera manufacturers, said the price of labor is becoming increasingly uncompetitive in China, a nation of 1.3 billion people, which is supposed have an unlimited labor force.

Wages in Shenzhen have risen by almost 50 percent during the past five years, according to Xie. In 2004, he moved his factory from Shenzhen to Vietnam and hired more than 200 local staff. "In Shenzhen, I have to pay a worker 1,500 to 3,000 yuan per month, but in Vietnam the wage is around 800," he said. "And I can see that costs are rising in Vietnam too, but at a slower rate than in China." In response, Xie is now considering moving production to Thailand or Cambodia, where labor costs are still low.

"The economy is no better than it was during the 2008 global crisis and I believe both Chinese and foreign companies are under great pressure," he said. "We can't control costs, and so we have to migrate, like herdsman chasing water and pastures."

However, labor costs in China are still lower than in most other places, particularly developed economies, according to Wang Rongjun. He said the average wage in the Chinese manufacturing sector is still only around 15 yuan an hour, compared with the minimum hourly wage of more than 40 yuan in the US, even at the lowest level.

China's economic rise has been built first and foremost on the efforts of low-waged workers and the country will continue to benefit from that for a long time to come, according to Wang.

"For most American flag retailers, it is just a practical way of doing business, and the cheaper price, resulting from lower costs for labor and materials, is the main reason Chinese goods dominate shelves around the world," said Wang Rongjun.

Contact the reporter at pengyining@chinadaily.com.cn

Relief reaches isolated village

Relief reaches isolated village

Rainfall poses new threats to quake-hit region

Rainfall poses new threats to quake-hit region

Funerals begin for Boston bombing victims

Funerals begin for Boston bombing victims

Quake takeaway from China's Air Force

Quake takeaway from China's Air Force

Obama celebrates young inventors at science fair

Obama celebrates young inventors at science fair

Earth Day marked around the world

Earth Day marked around the world

Volunteer team helping students find sense of normalcy

Volunteer team helping students find sense of normalcy

Ethnic groups quick to join rescue efforts

Ethnic groups quick to join rescue efforts

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Health new priority for quake zone

Xi meets US top military officer

Japan's boats driven out of Diaoyu

China mulls online shopping legislation

Bird flu death toll rises to 22

Putin appoints new ambassador to China

Japanese ships blocked from Diaoyu Islands

Inspired by Guan, more Chinese pick up golf

US Weekly

|

|